Disc coupling is an intermediary between the prime mover and the driven device, which prevents damage to these two devices in abnormal conditions and excessive forces.

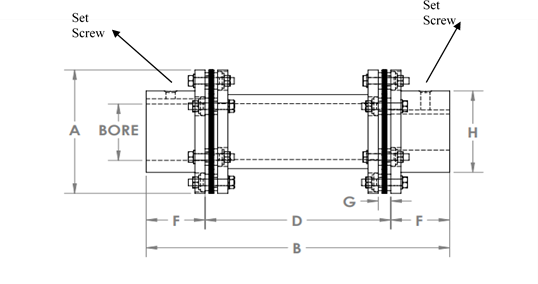

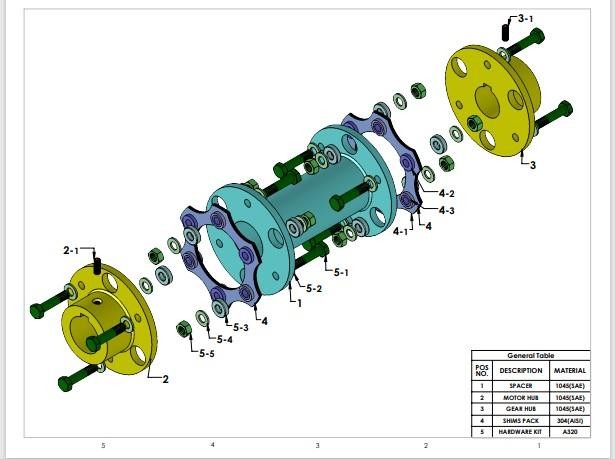

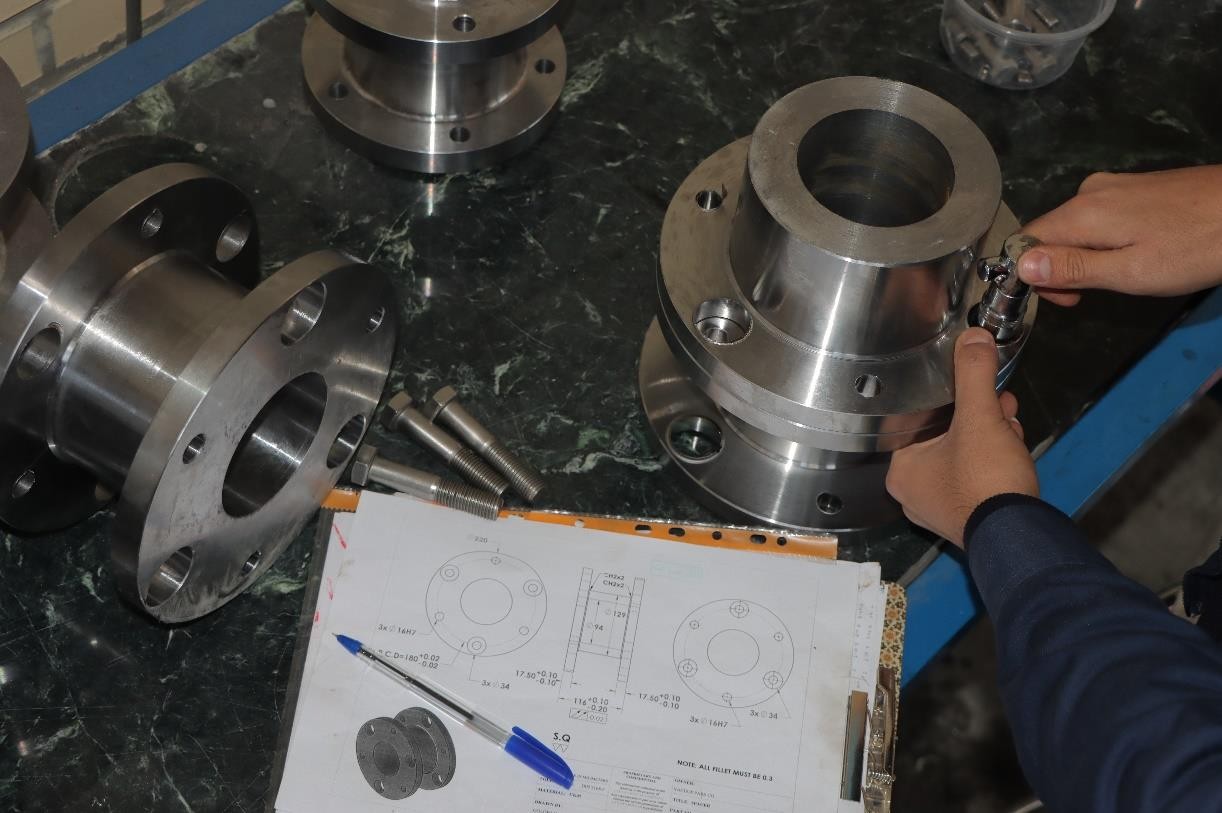

In simple terms, the structure of disc couplings is such that the coupling is connected to the devices with two flanges. Between the coupling, there are narrow metal parts that connect the two sides. These thin parts are called disk packs. By changing their form, disc packs can also control the misalignment between the shafts of two devices.

The mentioned disc packs are connected to each other and to the coupling body with screws. If excessive force is applied, the connecting screws will be cut due to the applied torque and the connection between the two devices will be interrupted.

The advantages of disc couplings can be stated as follows:

| Smooth transmission of torque |

| Eliminating angular and axial misalignment between two devices |

| Eliminating excessive torques and torsional vibrations and not transferring them to another device |

| The possibility of creating electrical insulation |

| Eliminating axial loads between two devices |

| Absence of backlash and wandering (accurate transfer of movement) even with the change of direction of rotation |

| No loss of torque (about 99% efficiency). |

| Long life without the need for periodic repairs or replacements |

| Can be used at high speeds |

Long life without the need for periodic repairs or replacements

Disc couplings are made in two types:

In the two-disc type, an intermediate piece is placed between the two discs.

Two discs

| Axial load control | Torque control | Non-collinearity control

Axial |

Angular misalignment control | Electrical insulation | |

| Yes | Yes | Yes | Yes | No | Single disc |

| Yes | Yes | Yes | Yes | Yes | Two discs |

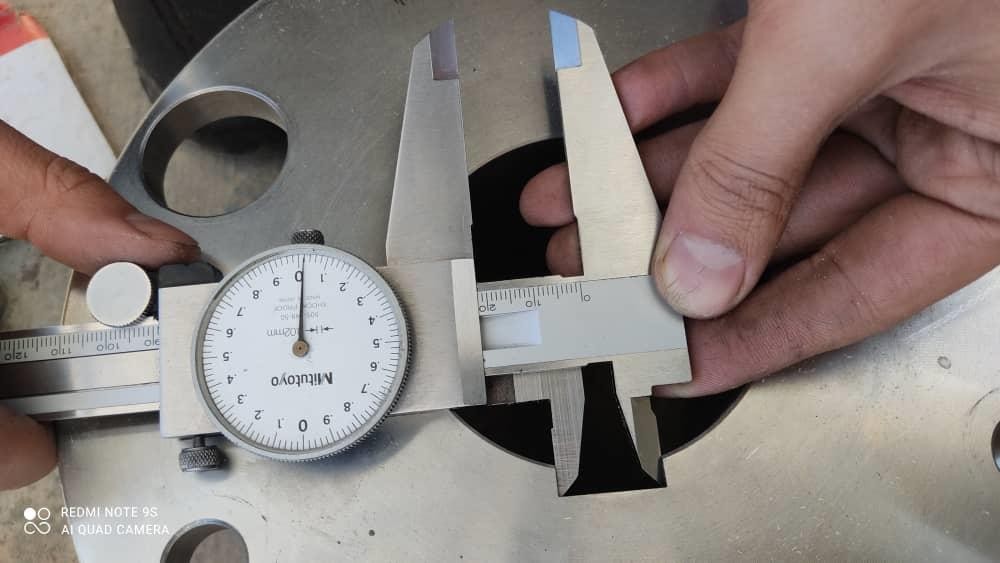

The main advantage of the production disc couplings is the material used to make the disc packs. raw materials for making these sensitive parts,

It is chosen in such a way that:

1- At the beginning of the movement, apply the minimum load to the bearings of the devices. 2-Having proper flexibility and at the same time low weight to reduce the application of dead load to the bearings of the connected devices.

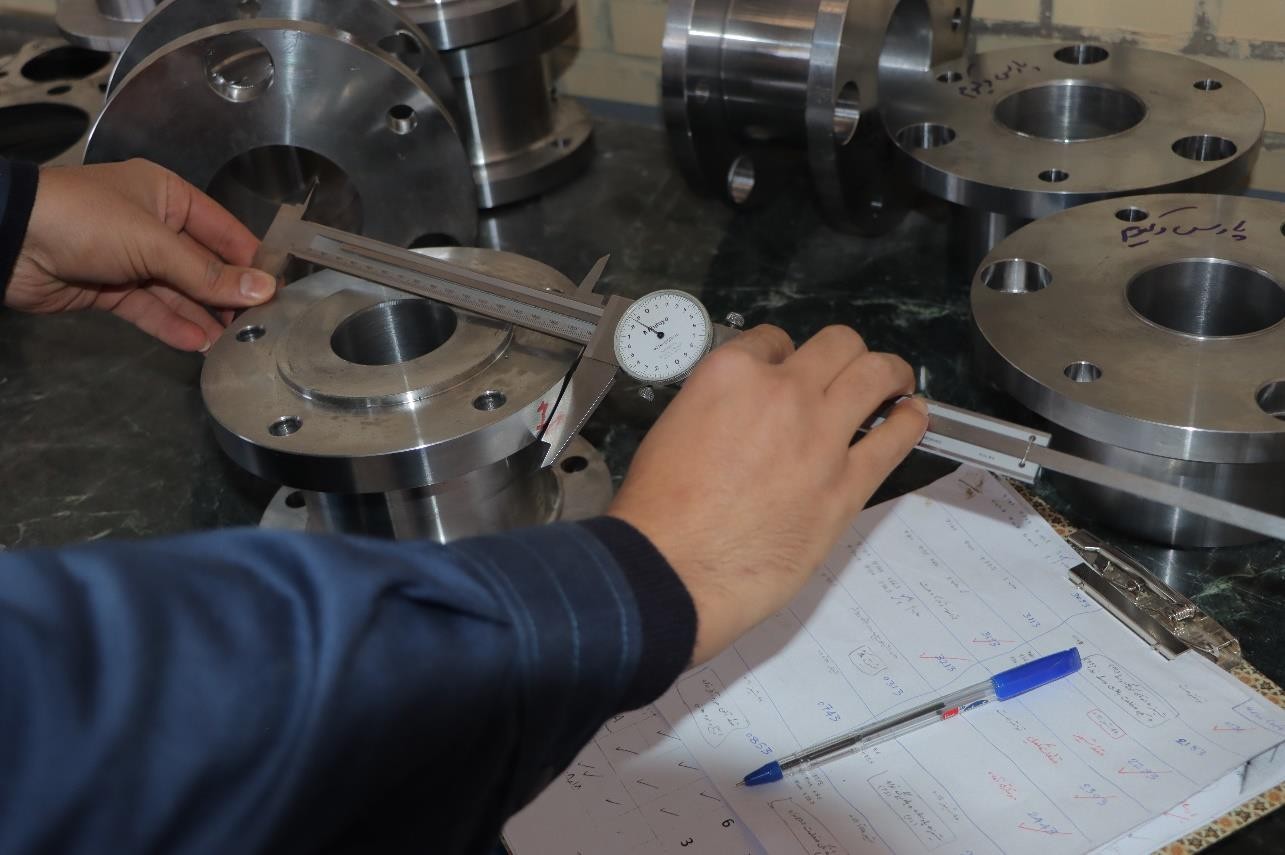

Due to the high speed of rotation of the coupling, the balance of the parts, especially the middle discs, is of particular importance. If the coupling is not properly balanced, it will eventually cause pressure on the bearings of the devices and their failure.

Azin Sanat Tavanmehvar., Ltd. is a manufacturing company, an industry that operates in the field of carbon fiber drive shaft production. The management of the company has put the slogan “doing work with the best quality of the company’s advertisement” on its agenda and asks its managers and employees to do their best to establish the said standard. .

All the rights of this website belong to Tavanmehvar Azin Sanat Company. © 2020